Programmable Logic Controllers (PLC)

Programmable Logic Controllers (PLC) Specification

- Country Of Origin

- India

- Type

- Plc Based Systems

- Material

- MS

- Warranty

- 1 year

- Features

- Good Quality

- Surface Finish

- Polished

Programmable Logic Controllers (PLC) Trade Information

- Minimum Order Quantity

- 1 Number

- Delivery Time

- 7 Days

About Programmable Logic Controllers (PLC)

PLC in Electroplating Industry

In the electroplating industry, Programmable Logic Controllers (PLCs) play a crucial role in automating and controlling various processes involved in metal finishing and surface coating. PLCs streamline operations, ensuring the electroplating plant runs efficiently and produces high-quality finishes. With precise control over variables such as temperature, current, voltage, and chemical dosing, PLCs ensure consistency and reliability across the entire electroplating process.

Key Features of PLCs in Electroplating Plants: Automated Control: PLCs manage multiple critical parameters such as voltage regulation, current control, temperature, and timing. This ensures uniform plating and improves overall production efficiency Real-Time Monitoring: PLCs continuously monitor the entire electroplating process, making real-time adjustments to maintain optimal conditions. They track equipment performance, detect deviations, and instantly correct them, minimizing defects.Fault Detection & Safety: PLC systems include diagnostics to identify issues early. Fault detection mechanisms trigger alarms for malfunctions, minimizing downtime and reducing risks to workers and machinery.Data Logging & Reporting: PLCs gather data on all aspects of the electroplating process, providing insights into production trends, enabling continuous improvement, and ensuring quality control.Energy Efficiency: By optimizing energy use in the plating process, PLCs help reduce electricity consumption, cutting down on costs while promoting sustainability.Customizable Solutions: PLCs can be programmed to cater to specific plating requirements, whether for barrel, rack, or continuous plating systems. They adapt easily to manual, semi-automatic, or fully automated plants.

Benefits of Using PLCs in Electroplating: Improved Productivity: Automation speeds up repetitive tasks and reduces the need for manual intervention, increasing throughput. Consistent Quality: Automation ensures that all metal surfaces receive uniform treatment, improving product quality and reducing reworks. Enhanced Safety: By automating hazardous processes, PLCs improve worker safety and ensure regulatory compliance. Scalability: PLC systems can be upgraded or expanded to meet increasing production demands or introduce new plating technologies.Waste Reduction: Precision in chemical dosing and process control minimizes waste, lowering operational costs and environmental impact.

At Sri Sai Electroplating Automation Private Limited, we are experts in providing turnkey automation solutions for electroplating plants. Our PLC systems are custom-designed to meet the needs of your electroplating operations, enhancing performance and reliability across all aspects of surface coating and metal finishing processes.

Frequently Asked Questions (FAQ)

1. What is a PLC, and why is it important in electroplating plants?

A Programmable Logic Controller (PLC) is an industrial control system used to automate and monitor processes in electroplating plants. It ensures precise control over parameters like voltage, temperature, and chemical dosing, leading to better plating quality and higher production efficiency.

2. Can PLCs be customized for my electroplating process?

Yes, PLCs can be programmed and customized based on your plants specific requirements. Whether you operate a manual, semi-automatic, or fully automated plant, we at Sri Sai Electroplating Automation Pvt. Ltd. design tailored solutions to fit your needs.

3. How does PLC automation improve safety in electroplating plants?

PLCs reduce the need for manual intervention in hazardous processes by automating tasks, which minimizes the risk to workers. Additionally, built-in fault detection systems alert operators to any malfunctions, preventing accidents.

4. Can a PLC system help with reducing energy costs?

Yes, PLC systems optimize energy use by regulating power consumption based on the specific needs of the electroplating process. This reduces unnecessary energy usage, lowering electricity costs.

5. What types of electroplating processes can be automated using PLCs?

PLCs can be used in various electroplating applications, including barrel plating, rack plating, continuous plating, and more. They are adaptable to multiple industries and metals, including gold, silver, copper, nickel, and chrome plating.

6. How do I maintain a PLC system?

Regular maintenance is essential for keeping your PLC system in good working order. Routine checks, software updates, and proper training for operators can help ensure smooth and efficient operation.

For more information on how our PLC solutions can benefit your electroplating plant, contact us at Sri Sai Electroplating Automation Private Limited.

Company Details:

Sri Sai Electroplating Automation Private Limited

Design and Manufacturer for Surface Coating and Metal Finishing Plant

Corporate Office Address:

Shiv Jyothi Towers, First Floor, Plot No. L 253,

New Door No. 36, 2nd Street, Periyar Nagar,

TNHB Colony, Korattur, Chennai - 600 080.

Factory Address:

Plot No.T382, SIDCO Womens Industrial Estate,

Thirumullaivoyal, Chennai - 600 062.

CIN: U28222TN2024PTC170671

GSTIN/UIN: 33ABNCS5795F1ZU

Website:www.electroplatingautomation.com

Email: sales@electroplatingautomation.com

Contact Number: 044 - 31000142

We specialize in designing and manufacturing electroplating plants that integrate advanced PLC systems, ensuring enhanced productivity, safety, and process control. Reach out to us for expert consultation and solutions tailored to your electroplating needs.

Let Sri Sai Electroplating Automation Pvt. Ltd. help you take your electroplating processes to the next level!

Industrial-Grade Construction

Our PLC-based systems are constructed from high-quality mild steel (MS), ensuring strength and durability for demanding industrial environments. The polished surface finish offers both corrosion resistance and a sleek, professional look. These PLCs are meticulously manufactured in India, blending local expertise with stringent quality standards to deliver a reliable automation solution for your process needs.

Reliable Warranty and Support

With a 1-year manufacturers warranty, you have assurance of dependable performance and after-sales support. Our dedicated team assists with installation guidance, troubleshooting, and ongoing maintenance, making us a preferred supplier for customers across India. This warranty helps protect your investment and ensures continuous operation of your industrial systems.

FAQs of Programmable Logic Controllers (PLC):

Q: How can a PLC-based system improve my industrial automation processes?

A: A PLC-based system helps streamline automation by managing complex control tasks with high precision and consistency, thereby reducing manual intervention and increasing production efficiency.Q: What are the material and finishing specifications of your PLC units?

A: Our PLC units are crafted from mild steel (MS) and feature a polished surface finish, ensuring durability, longevity, and resistance to corrosion, perfectly suited for industrial environments.Q: When does the 1-year warranty period start for these PLC systems?

A: The 1-year warranty starts from the date of purchase, giving you comprehensive coverage and support for any manufacturing defects or faults that may occur during normal operation.Q: Where are your PLCs manufactured and supplied from?

A: All our programmable logic controllers are domestically manufactured and supplied from India, following rigorous quality standards to cater to the needs of various industries across the country.Q: What is the process for installing these PLC-based systems?

A: Installation involves mounting the PLC unit, connecting required inputs and outputs, and configuring the system settings as per your application. Our team can provide guidance and documentation to ensure a smooth setup.Q: How are these PLCs typically used in manufacturing settings?

A: These PLCs are primarily used for automating machinery, monitoring production lines, and controlling various industrial equipment to optimize operational workflows and minimize human error.Q: What are the main benefits of choosing your PLC systems as a manufacturer or supplier?

A: Choosing our PLC systems means you receive high-quality, durable automation solutions backed by a 1-year warranty, reliable Indian manufacturing, and support that enhances productivity and reduces downtime in your operations.

Price 35000 INR/ Piece

- Minimum Order Quantity

- 1 Number

- Delivery Time

- 7 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electroplating Plant Category

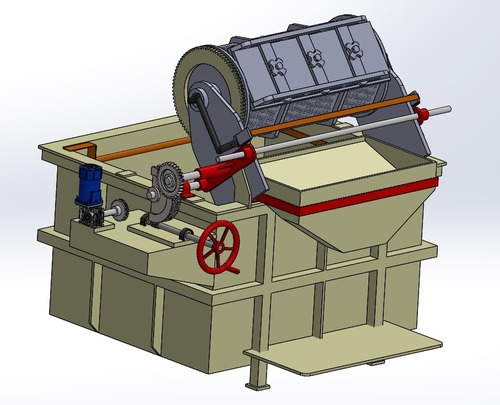

Electroplating Barrels

Minimum Order Quantity : 01 Piece

Automatic Grade : Automatic

Drive Type : Electric

Color : Multicolor

Warranty : 1 Year

Electroplating Equipment

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Drive Type : Electric

Color : Blue

Type : Electroplating

Warranty : Yes

Industrial Electroplating Plant

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Drive Type : Electric

Color : White

Type : Electroplating Plant

Warranty : Yes

Electroplating Automatic Rack Plant

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Drive Type : Electric

Color : Blue

Type : Electroplating Plant

Warranty : Yes

Send Inquiry

Send Inquiry Send SMS

Send SMS